BoxBay Automated Container Terminal - DP World

BoxBay Automated Container Terminal

Worlds first

Container High Bay Store System

YEAR

2019

LOCATION

Jabel Ali, Dubai

EMPLOYER

DP World

Use

MRO

STRUCTURE

Steel

SEGMENT

Infrastructure and Heavy Civil Construction

SUB-SEGMENT

Container Terminal

PROJECT STATUS

Completed

Amazon build to suit (BTS), Fulfilment Centre for phase one is located in Industrial City of Abu Dhabi (ICAD) which is a free zone dedicated to industrial processes. Spanning across 40 sq. km. ICAD is part of Musaffah, a popular industrial district located in the southwest of Abu Dhabi. The master development is one of the most important economic zones in the UAE housing several factories and a port.

Once soil has been improved and the plot leveled by another contractor, RAQ will begin the execution project for the Amazon fulfillment center. Client targeted time duration for the completion of “Build to Suit (BTS), Fulfilment Centre (FC) Phase 1 – “AUH1” project will be in 14 months (420 days).

The project has been directly commissioned by Amazon USA and is run with their standards.

As always, we plan our project in phases and divide areas in zones for easy deployment of resources.

Erection of steel starts of in Zone 2. We start the erection from the left; this is the absolution center of the entire building.

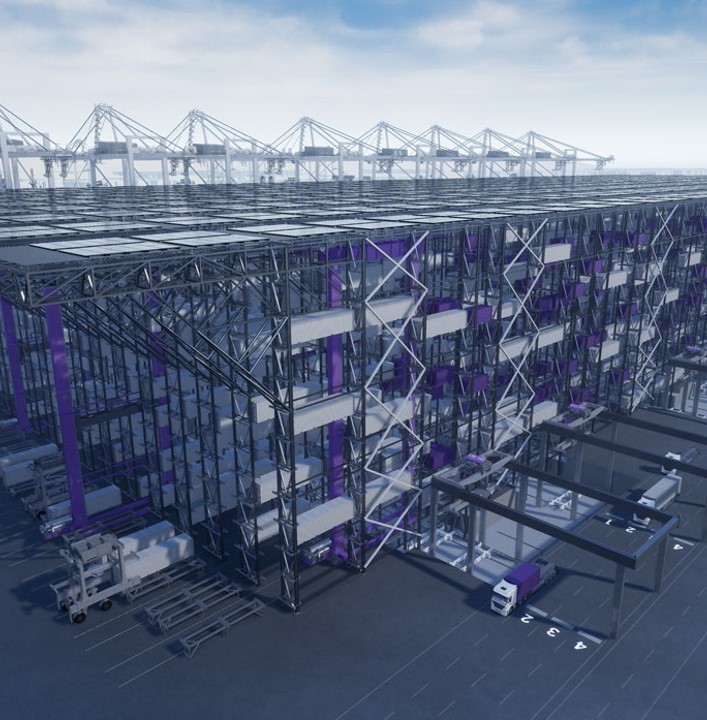

The project involved RAQ’s expertise in steel supply and erection. The project is design and construction of of High Bay Storage facility. BOXBAY is offering different solutions for container storing and handling by means of High Bay Storage (HBS) systems – a disruptive technology that significantly improves operations at container terminals.

By being fully automated it has direct access to each container, eliminating unpaid and unproductive reshuffling. It also features significant gains in handling speed, energy efficiency, safety and a major reduction in operating costs.

The joint venture brings together decades of experience in container terminal logistics at DP World and AMOVA’s high bay storage handling for metal products that weigh as much as 50 tons each in racks as high as 50 meters.

The majority of the time, at major ports, shipping containers are stacked up 6 or 7 high and await cranes to empty them onto ships for transport. This approach not only takes up a lot of space but also makes it difficult to find and pick up the right box.

DP World, a port operator based in Dubai, has developed an innovation that it claims will save time and space.

The “BoxBay” storage system stacks containers 11 stories high on a steel frame. In ports, when containers are stacked on top of each other, reaching a container lower in the stack means moving those above it. According to DP World, BoxBay, developed in partnership with the SMS group of Germany, lets cranes pick up containers directly from the ground without rearranging those above.

DP World, a port operator based in Dubai, has developed an innovation that it claims will save time and space.

The “BoxBay” storage system stacks containers 11 stories high on a steel frame. In ports, when containers are stacked on top of each other, reaching a container lower in the stack means moving those above it. According to DP World, BoxBay, developed in partnership with the SMS group of Germany, lets cranes pick up containers directly from the ground without rearranging those above.

×

Geocoding Error Occured.

Tried to Geocode:

Error Type:

Please be sure to follow the tutorial on how to setup the Google APIs required for the Advanced Google Map Widget.

Google Map API Key Tutorial